Chronos - a renovation for industrial relic

Introduction

Chronos, built for a cafeteria, was renovated from an old industrial brick building. In this project, an automatic system by an industrial robot arm was implemented on-site to ensure the quality of steel structure construction. Because the site is adjacent to an obsolete railway spotted by one rail merging smoothly into the other, this design reflects this geometrical transition by fusing a spiral crystal volume into a solid brick as a metaphor for linking the past to the future.

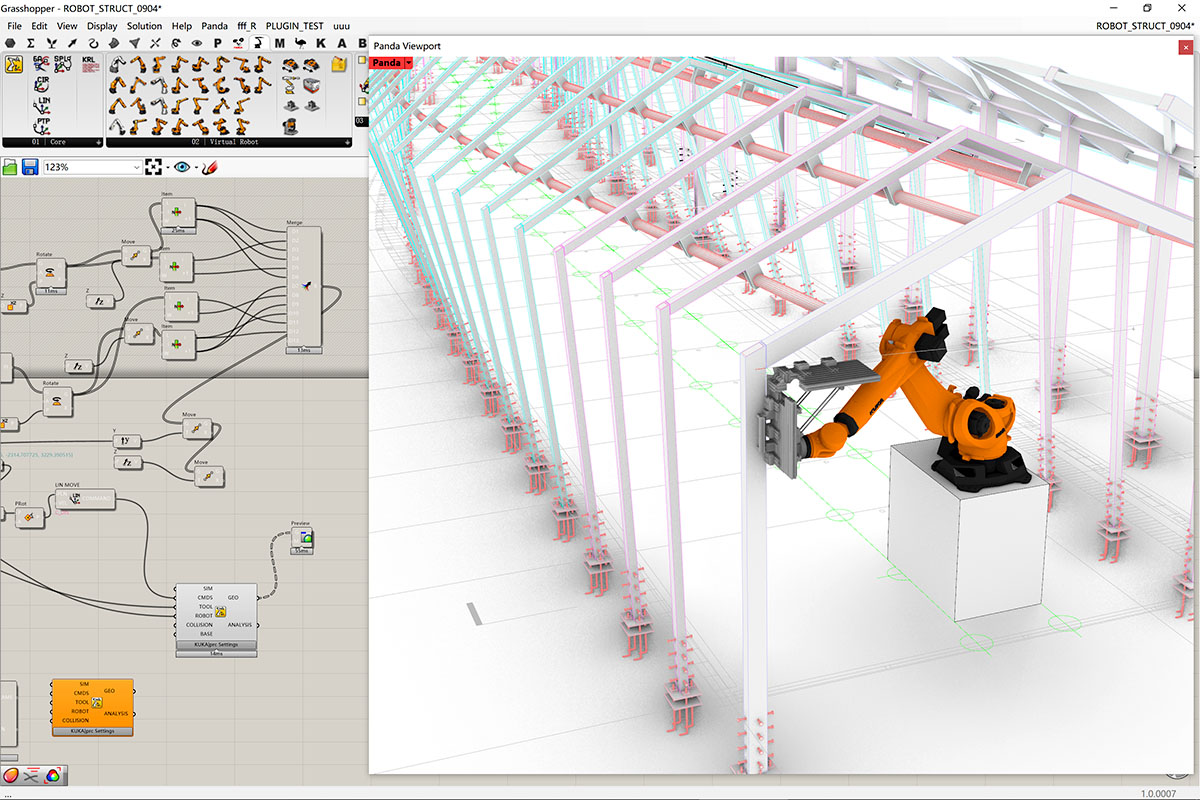

Because we pursued a crystal feel from the inside out as the original design proposal, an innovative surface structure was created: the steel structure, as biomimicry of a snake skeleton, was hidden in a curtain wall of U-shaped glass, and the spiral form was assembled by serial sections which have gradual variations from the brick build to an open-ended side. Four round beams, concealed latterly in upper compartments for hosting lighting and ventilation, as centre spine are applied to fuse these sectional frames. After a calculation, the steel frame must be precisely fixed within a tolerance of less than ±5mm to guarantee the glass will not collide with steel members. Hence, a centre ground rail allowed a robot arm cart to patrol the site. A cartesian coordinate system was created based on this rail to synchronize the physical site with the virtual space. Based on this coordinate, the customized robot system can play a crucial role in guiding every steel component to be fixed precisely in accordance with the digital model. Then, welding work was applied at the joint manually.

The U-shaped glass panels were cut and chamfered by a robot cutting station in specific lengths and angles before the tempered process. This procedure becomes another unforgiving demand on accuracy during the steel structure construction. After the steel frame structure was complete, this project was halted for half a year because of Covid-19. After a survey by Total Station before the curtain wall came into installation, the structure sagged with a bias of ±5mm during the vacancy, which is still acceptable according to the tolerance control. It took three months to complete the U-shape glass envelope by our team, who obtained expertise in this unique material in a former project, “Trees-parency”. ASW also developed a cable mechanism to effectively hold those panels in tilting outward proportion without compromising the quality of transparency.

Specs

Location: Dongfeng Park, Beijing China

Client: Capital Land

Built: 2021

Area: Length 70m, Width 5m, 350sqm

Architect: Dr. Yu Lei

Structure Engineer: SGI and Zuo Qing

Team: Yang Daoqian, Shi Ji, Zhu Jianmin, Winter Ma

Night view

Night view

Interior view in daytime

Interior view at night

Detail of the U-shaped glass curtain wall

Original site view

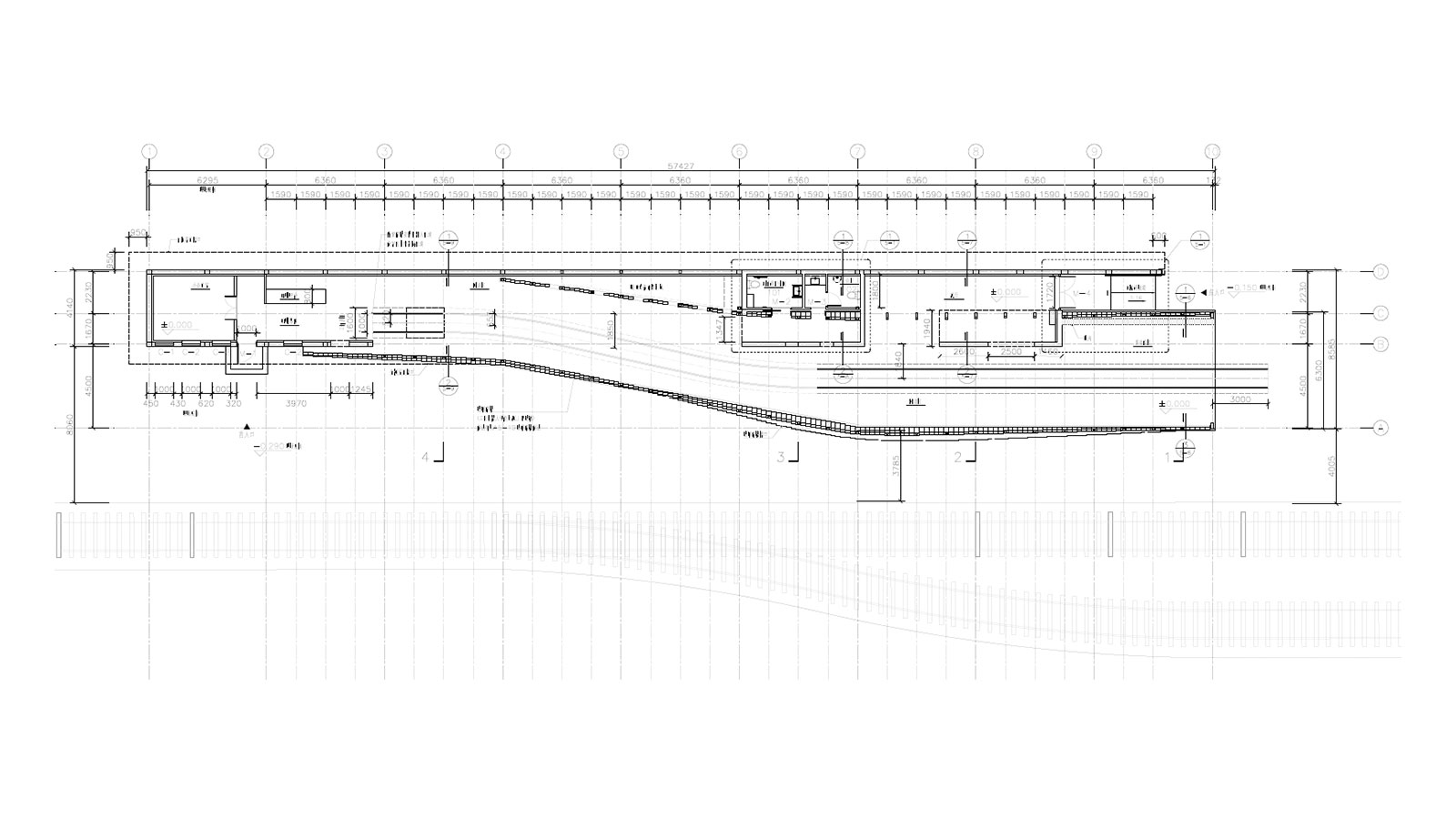

Drawing- floor plan

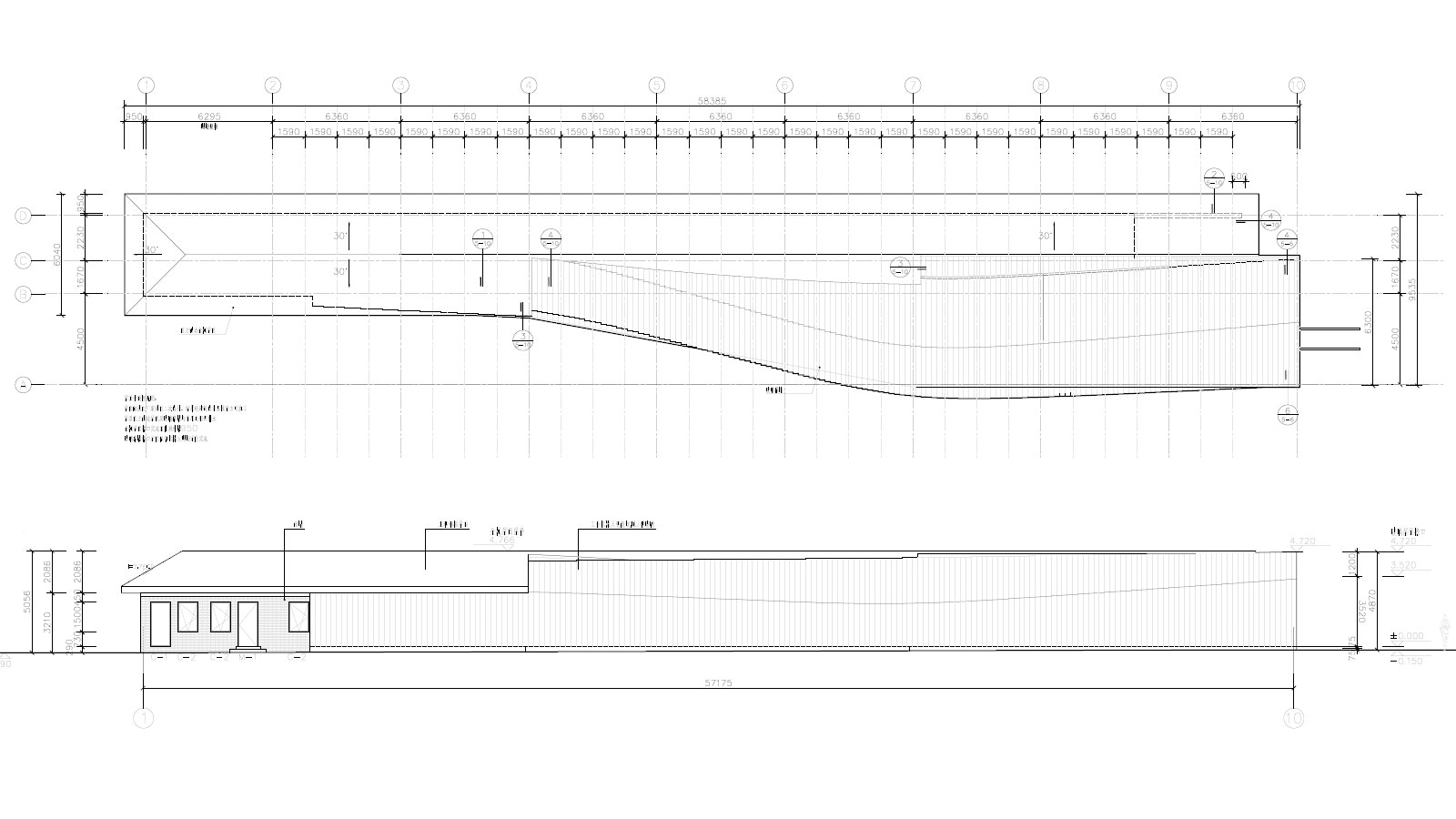

Drawings-roof and front elevation

Rotot on-site construction

Robot on-site construction

Robot on-site construction

Robot on-site construction

Detail of robot end-effector for steel frame construction